PERSONALIZED SERVICE

We assist you in all stages of production, from co-design to prototyping, from the construction of the molds to the choice of materials, molding and processing necessary for the success of the product.

WHAT WE DO

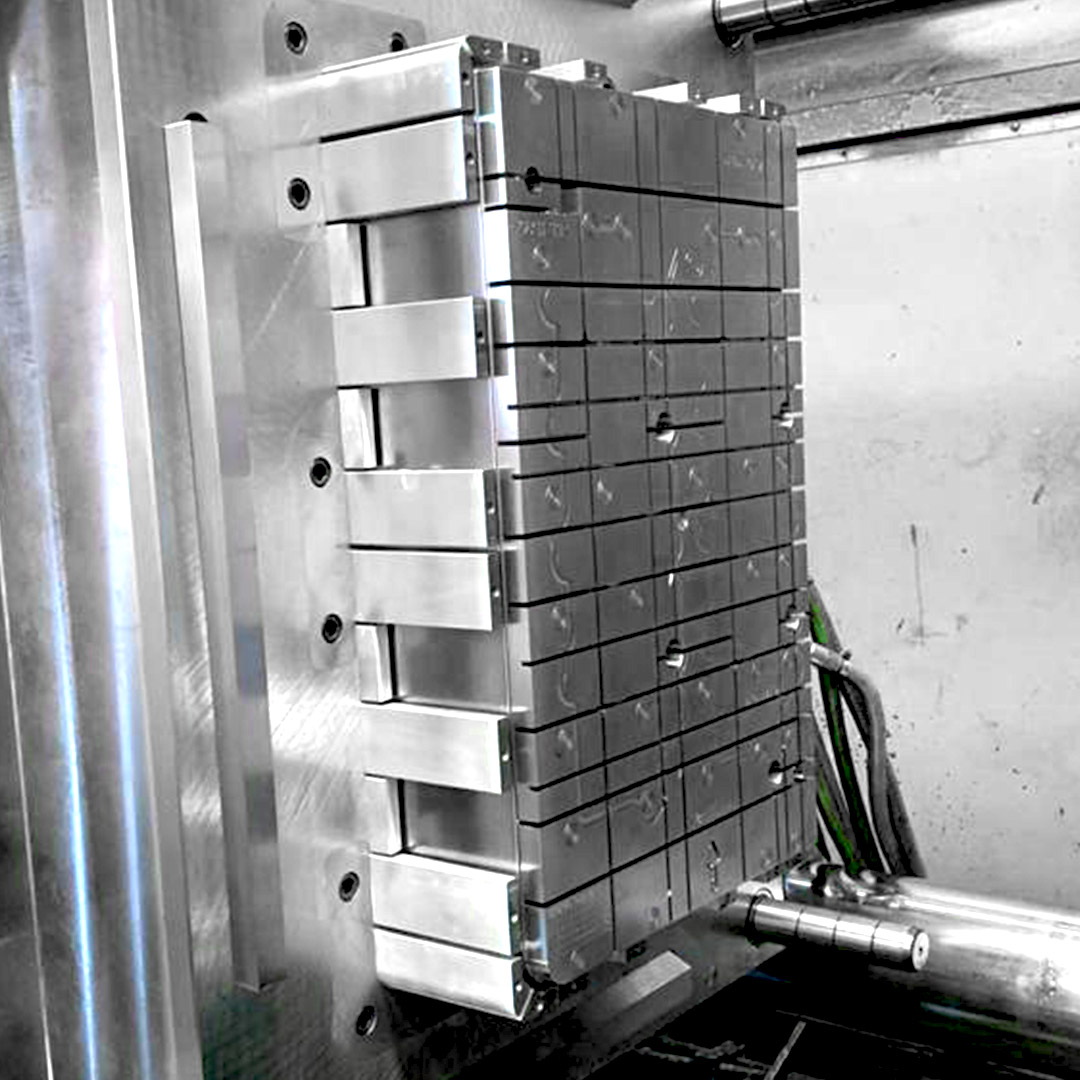

REALIZATION OF MOLDS

The realization of the molds is done in collaboration with our partner companies, with specialized departments and highly professional operators, using advanced machinery.

We use, for the construction of the molds, the best steels and metal alloys to ensure that the final result is perfect. The more the mold is made in a flawless manner, the higher the quality of the molded product will be.

Today, we can offer a complete service, from consulting to design, up to the molding of the finished product.

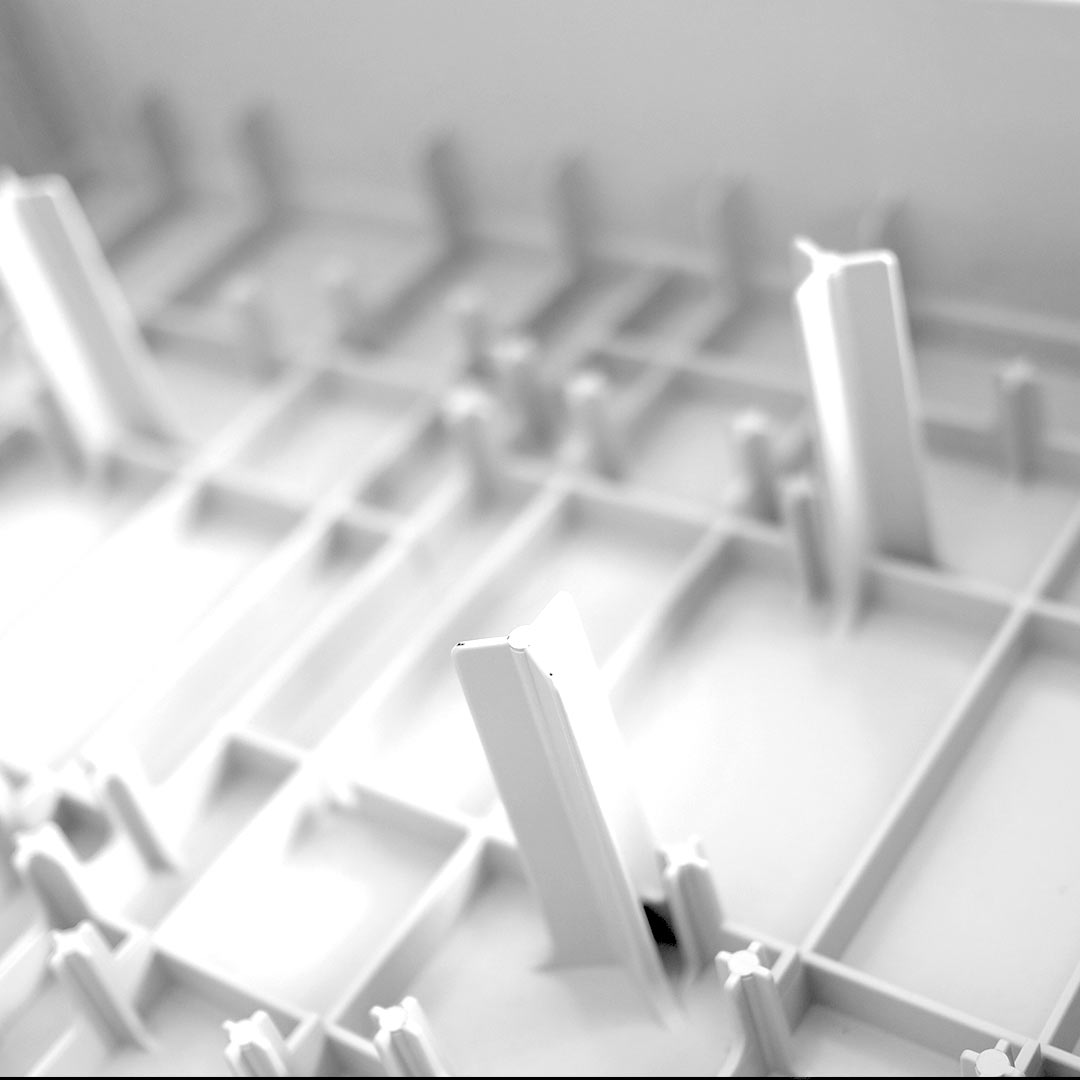

PLASTIC MOLDING

Our many years of experience in the field of molding, allows us to manage any project with the highest technical competence. The company has a fleet of machines consisting of 11 injection molding machines, electric and hydraulic, from 70 to 600 tons, all robotic and automated. This allows a continuous production cycle for the production of small or high quantities.

The constant collaborations in various sectors have allowed us over the years to constantly evolve and improve our production processes to perfection, from the point of view of quality and efficiency.

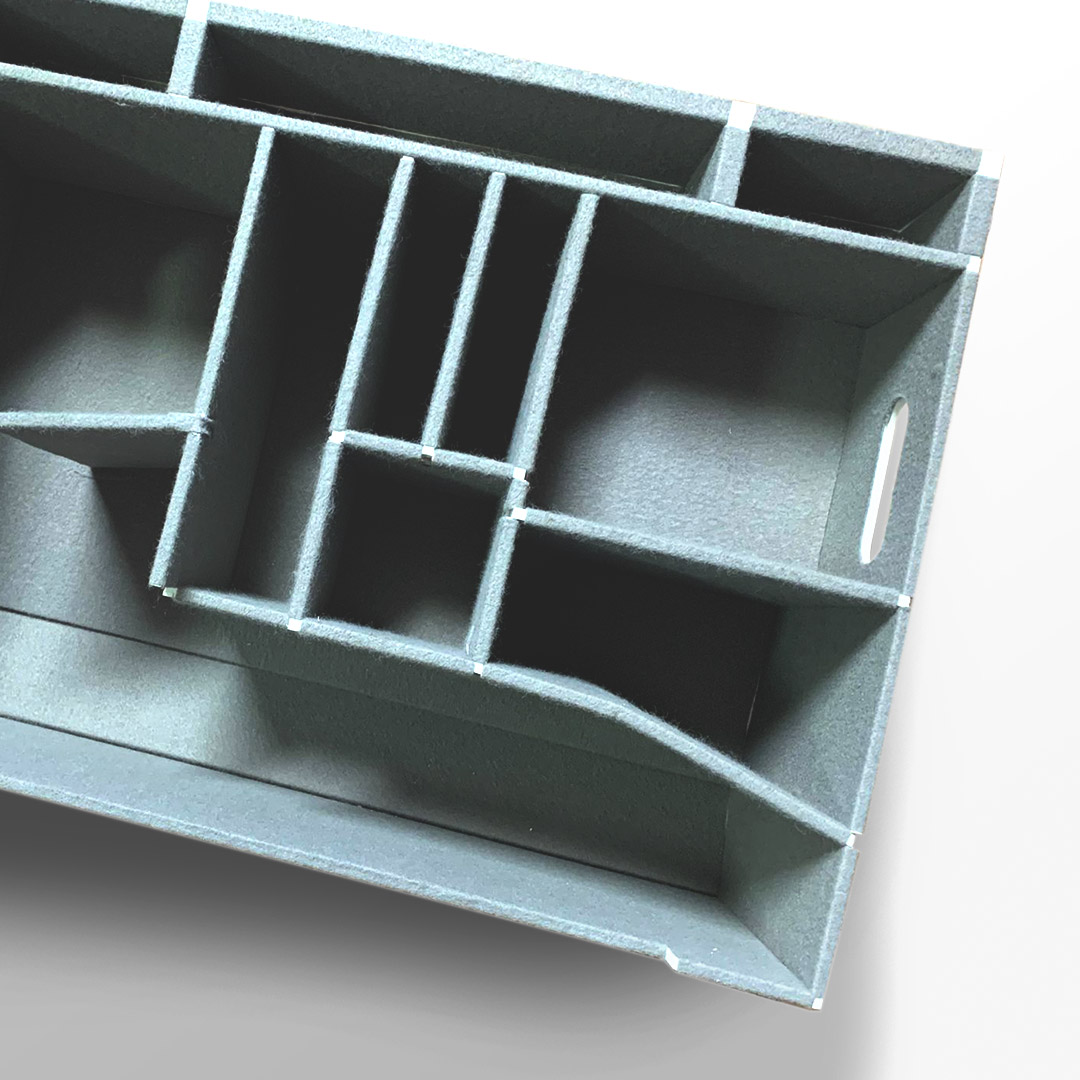

THERMOFORMING

Thermoforming is a production process used extensively in industrial packaging.

The company has sheet and reel thermoforming machines.

For our processing we use thermoplastic materials such as: ABS, ABS ESD, ABS+TPU, ABS+TPU ESD, HDPE, PS+PE, PS, PC, PC+ABS, but we also work on more specific needs according to our customers’ requests.

TRAFILING

Our plastic processing department includes two drawing lines for 45 and 60 diameters.

Thanks to our team of experts, we are always able to ensure quality products, meeting the needs of customers in the conception, design, production and final realization of thermoplastic profiles and components.

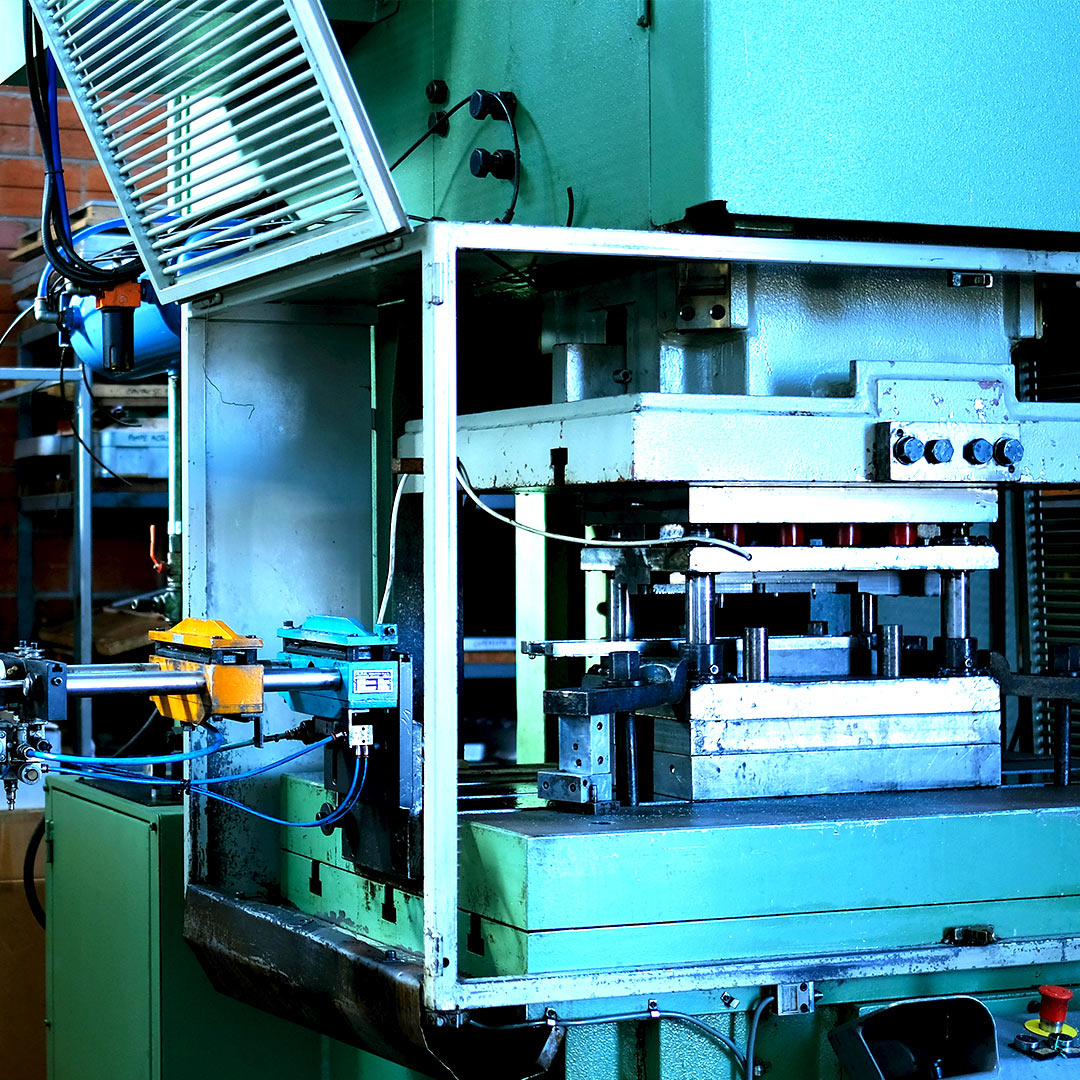

SHEET METAL WORKING

The department for the processing of sheet metal, consists of a fleet of machines consisting of 6 presses from 100 to 250 tons all automated. We can follow the entire processing cycle, having integrated new production technologies, such as laser cutting next to the classic processes (shearing, welding, bending, threading).

According to our customer’s needs, we can integrate additional services such as assembly, painting and other finishes.

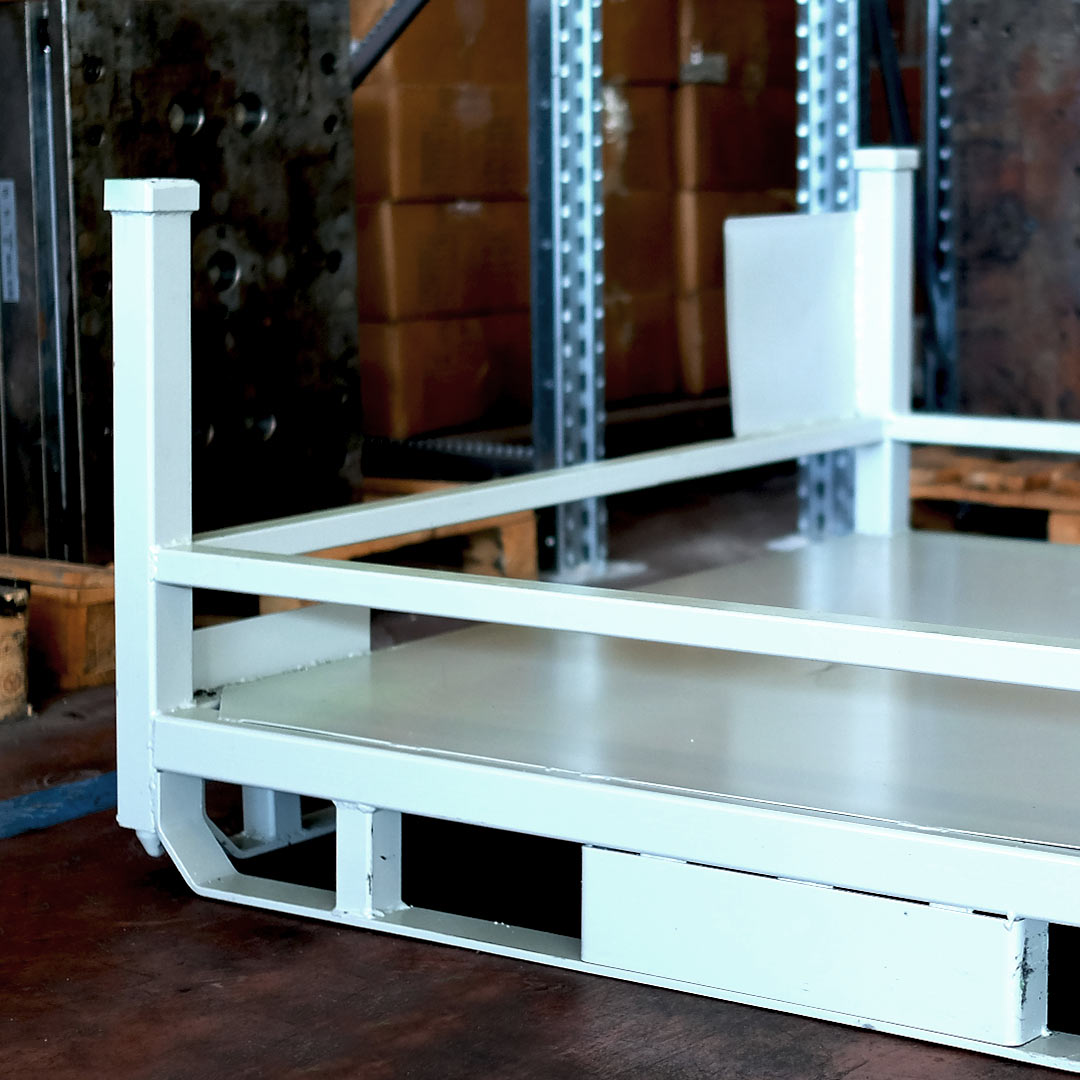

METAL CARPENTRY

Our company, in collaboration with partner companies, can realize specific containers in the field of industrial packaging, with different dimensions and characteristics.

Our experience combined with continuous technological improvement allow us to optimize processing and offer high quality at highly competitive costs.

Our cutting-edge machinery allows us to perform any type of processing, such as cutting, bending, welding.

MACHINING AND VARIOUS ASSEMBLIES

Part of our services include complete assemblies of plastic and sheet metal components.

We support our customers in their production processes, always ensuring competence and speed.

In the assembly phase we provide any type of machining necessary, such as milling, drilling, threading, welding, and various finishes.

INDUSTRIAL PACKAGING COMMERCIALIZATION

Since several years we realize and supply different types of containers and industrial packaging, of various colors and sizes, suitable for transport, storage, and product safety.

Equipped with means of transport for fast, safe and punctual deliveries

“Our Quality Control follows each stage of processing to identify any anomalies in production, correcting them according to the optimal production parameters.”