WE OPTIMIZE PRODUCTION PROCESSES

Feasibility study, Prototype, and preventive cost analysis, for a precise and punctual project

Thanks to the wide range of technologies and the experience gained over time we can create prototypes offering our customers, advice in the design phase, technical and production capacity, speed of implementation and confidentiality.

We assist you from design to prototyping until the production of the mold, we can develop, with the know-how and seriousness that has always distinguished us, the best solutions to be used for the realization of molds or models, ensuring maximum effectiveness with optimized costs and benefits.

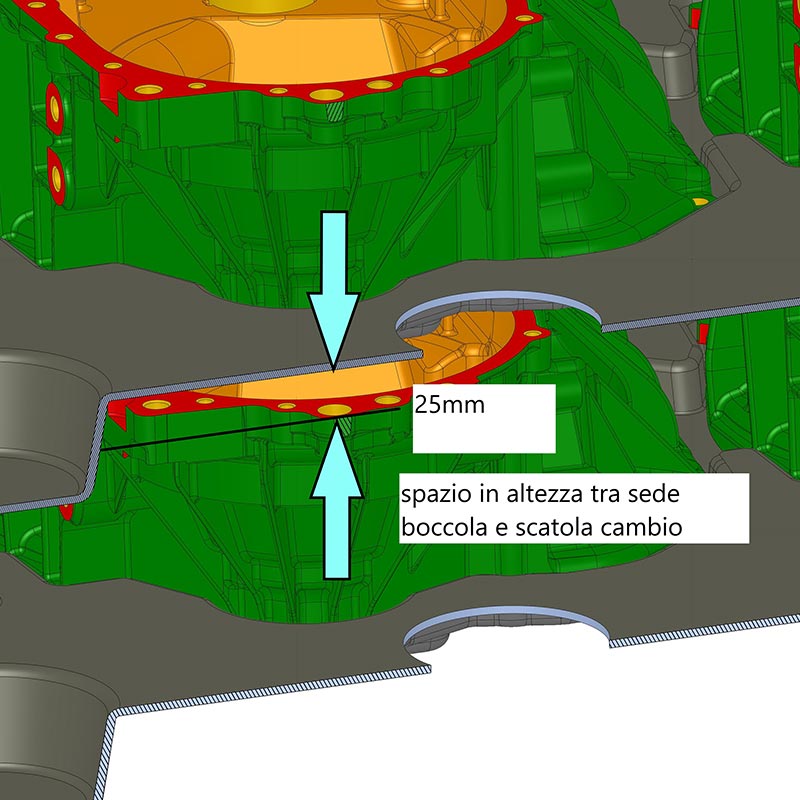

DESIGN

The design is the starting point for the realization of the molds, during which all the parameters of the product and the production process are defined.

Thanks to the continuous technological updating, we can offer our customers a professional service in the co-design and engineering of the products to be manufactured, always proposing the ideal technical solution for each request.

We are also able to offer a “reverse-engineering” service, to realize a project or a mathematical drawing starting from a model or an already existing element.

Per i nostri progetti ci avvaliamo del software Solidworks, nato appositamente per il disegno tridimensionale parametrico dedicato all’ingegneria meccanica.

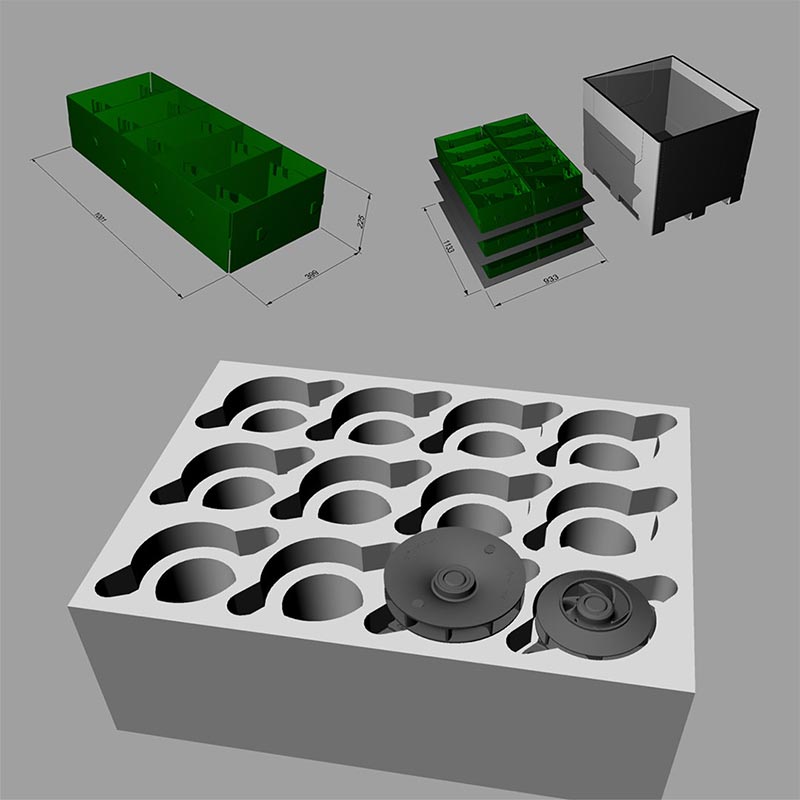

PROTOTYPING

Thanks to an efficient modeling and prototyping department, we can offer models and molds for prototypes and small series to be produced in different technologies such as thermoforming and injection molds.

Thanks to the collaboration with partner companies, we can provide the customer with functional prototypes, made through 3D printer technology or through silicone molds for larger samples, with a choice of materials that is closer to the characteristics of the finished product.

The construction of prototype molds allows to study molding processes or to evaluate the actual validity of an element, and then bring the experience made during the tests in the series molds.

The quality and rapidity of execution of the prototype moulds allows the realization of even complex components with high finishes in reduced times.